We welcome all readers to the 1st issue of the SMARTHANDLE newsletter!We are pleased to announce the publication of the 1st issue of the SMARTHANDLE newsletter! The project started in January 2023 and consists of 14 partners from 6 countries (Greece, Spain, Germany, Netherlands, Luxemburg, and Belgium). Our strong consortium has been working together to develop, deploy, validate, and promote smart and versatile manufacturing solutions within the 3 years duration of the project. Best wishes,

The SMARTHANDLE team |

|

|

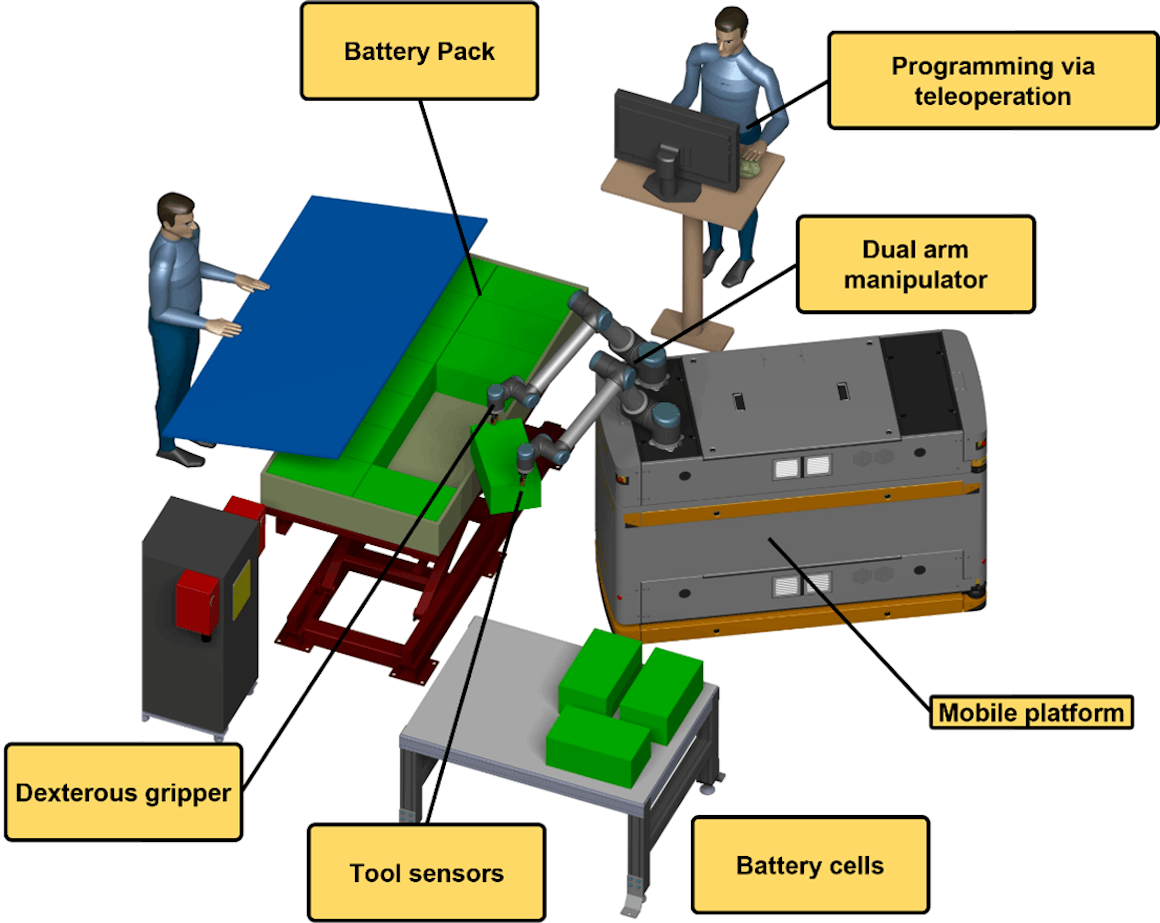

Resilient manufacturing lines based on smart handling systems Manual and automated production lines must evolve to “produce more and diverse with less”, while addressing important shortcomings such as product variabilities, lack of high-level autonomous reasoning and accurate adaptable control and holistic efficient planning systems. SMARTHANDLE will research technologies to address these needs and support European industry, by implementing: - intelligent agents providing dexterity for handling applications,

- AI based reasoning enablers

- Higher-level planning and coordination mechanism for successful deployment in real life use cases.

To demonstrate SMARTHANDLE solutions in real-life applications, 3 use cases have been designed from the field of consumer goods requiring delicate and high precision handling (contact lenses), Metal Industries, packaging of large variable section materials (aluminium) and automotive tier-1 suppliers, disassembly of complex products (batteries) involving dexterous operations that are not possible to implement with the existing technologies. Social and ethical aspects will be addressed, demonstrating benefits for workers by reducing their involvement in unsafe and unhealthy tasks, improving their working conditions when working in areas where the SMARTHANDLE reconfigurable solutions will operate. |

|

|

| Meet the partner #1 TECNALIA Research & Innovation is the largest centre of applied research and technological development in Spain, a benchmark in Europe and a member of the Basque Research and Technology Alliance.

Within SMARTHANDLE, TECNALIA is the project´s coordinator, as well as leader of the AI-based multi-level performance optimization. Read the full post |

|

|

| Meet the partner #2 Laboratory for Manufacturing Systems & Automation (LMS) is oriented on research and development in cutting edge scientific and technological fields.

Within SMARTHANDLE, LMS brings its competence in key enabling technologies in the areas of dexterity, system reconfiguration and multi-level reasoning. By leading activities for the planning and monitoring of handling operations, LMS will contribute to the design and implementation of AI-based tools for process planning, packaging planning, orchestration and shop floor digital twins. . Read the full post |

|

|

SMARTHANDLE's presence in events |

|

|

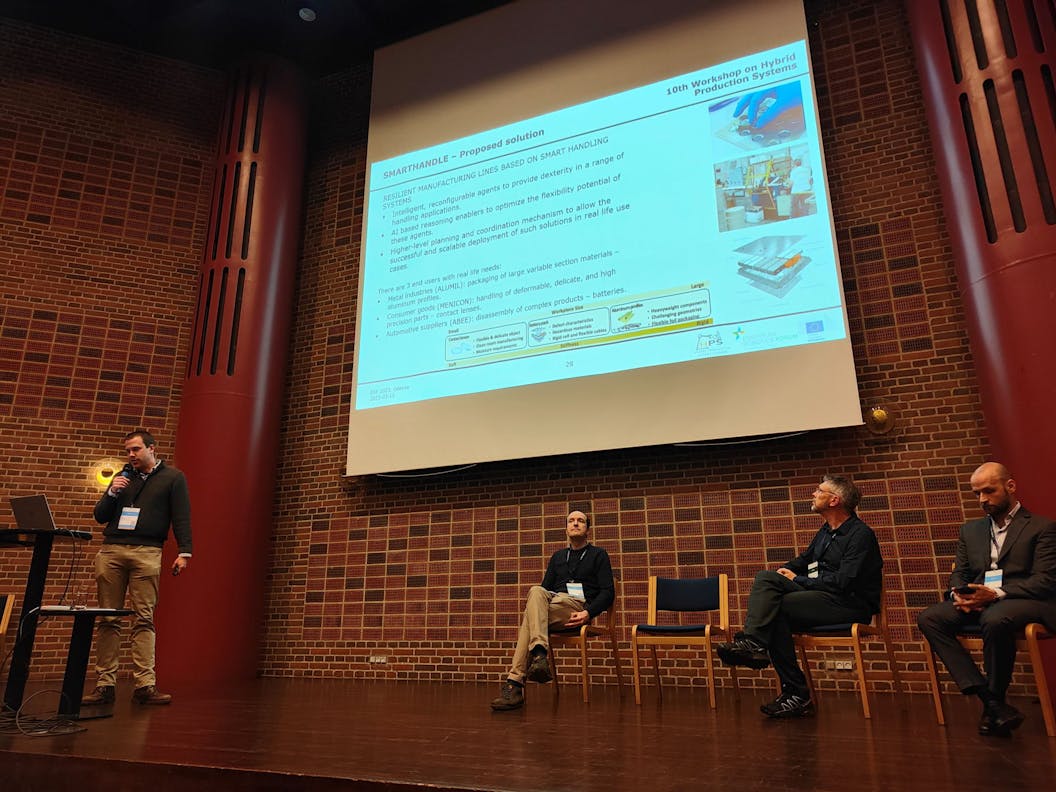

The SMARTHANDLE project was presented at the 10th Hybrid Production Systems workshop organised by Laboratory for Manufacturing Systems and Automation, during the ERF2023 conference in Odense, Denmark.

The workshop’s panel discussion on SMARTHANDLE project was on 15th of March 2023, 13:00-17:00.

During the session SMARTHANDLE's sister projects AgileHand Project, MASTERLY Project EU and #HARTU were presented as well.

The areas mainly addressed during the workshop were Agile Production, Robotics, AI, BigDataValue, Autonomy, Collaborative Robots and Cybersecurity in Robotics.

|

| |

|

| The 33rd edition of theETSEIB Forum took place at the Barcelona School of Industrial Engineering (ETSEIB) of the Universitat Politècnica de Catalunya - BarcelonaTech (UPC) from 2 to 5 May 2023. Organized by students, the forum aims to bridge the gap between companies and students, thus facilitating their integration in the job market. Around in the fair, jointly with some Research Centers and University Departments that presented research as a career opportunity. The fair also included talks, workshops and personal interviews. The Institute of Industrial and Control Engineering (IOC-UPC) had a stand in the fair on Tuesday, May 2nd, 2023. As one of the main EU-funded projects currently in progress at IOC-UPC, the SMARTHANDLE project was presented there and flyers with information about the aim, the consortium and other relevant information about the project were distributed to all the stand’s visitors. |

|

|

On September 26, SMARTHANDLE was represented by TECNALIA and LMS at the Manufacturing Partnership Day, organised by the European Factories of the Future Research Association (EFFRA), that took place physically in Brussels, Belgium. The event featured multiple sessions with project presentations and an exhibition area where more than fifty projects presented their ongoing work. This event was co-organized by EFFRA (the European Factories of the Future Research Association) and Factories of the Future and Made in Europe projects, brining together a network of around 400 manufacturing innovation and research professionals. Read more information here |

| |

|

SMARTHANDLE partners study visits, March 2023 |

|

|

On March 21st, SMARTHANDLE partners had the opportunity to visit Alumil's Factory at Kilkis, Greece! The visit was organised at Alumil's premises visiting the Aluminium extrusion line, the horizontal and vertical powder coating lines, the anodizing plant in Kilkis and the profile joining line. Particularly, the consortium visited Alumil's packaging lines, including the one that will be used for the SMARTHANDLE project! |

|

|

|

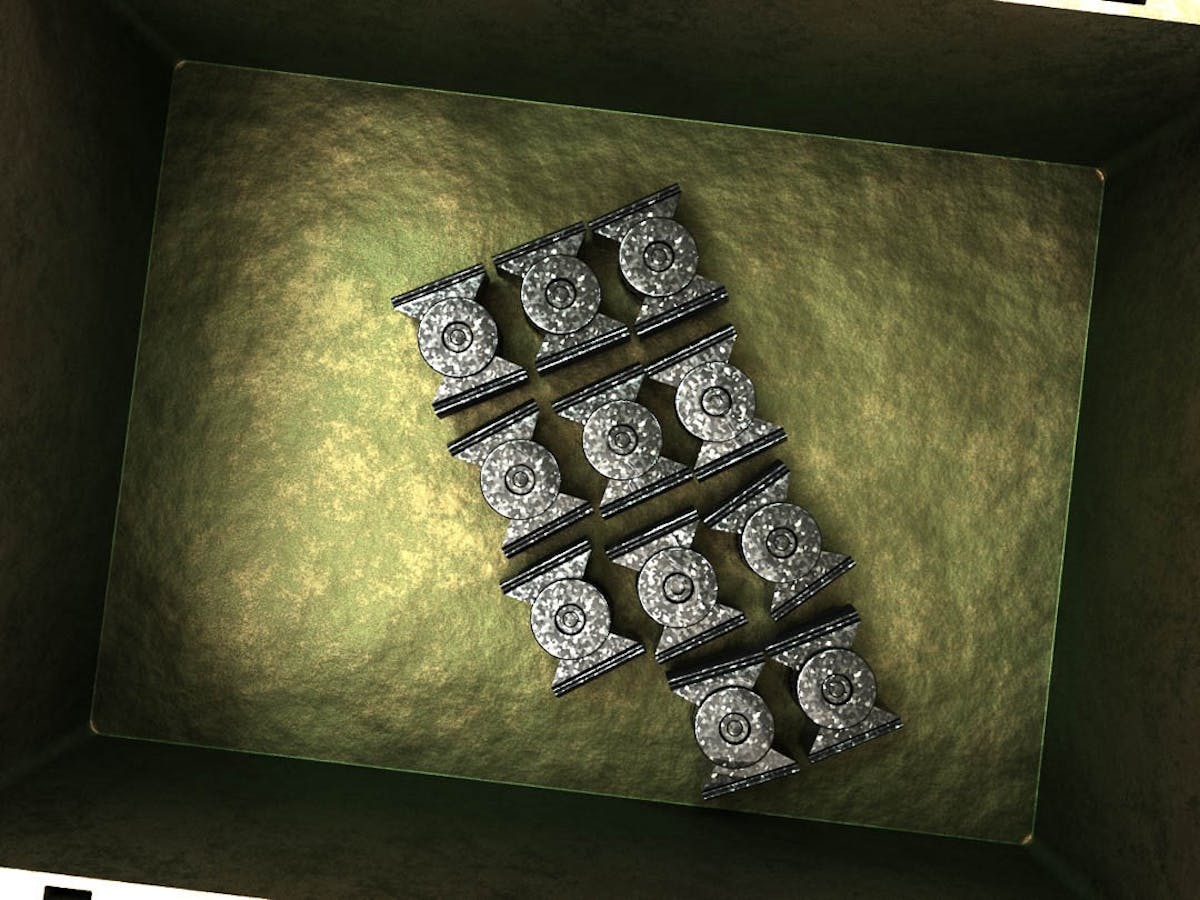

On March 28th, SMARTHANDLE partners had the opportunity to visit Menicon premises at Emmen, Netherlands!

During the visit, partners were presented the challenges regarding the contact lenses manipulation along the manufacturing process. These challenges are related to the lenses material, which is flexible, light, transparent and delicate to scratches and to hygienic.

So far, it was not possible to perform correctly the delicate manipulation of contact lenses with a proper automated solution. Therefore, the manipulation is done manually by workers at each single production stage, despite all the ergonomic and productivity problems related to that. To tackle these issues, SMARTHANDLE will develop an automated system, able to manipulate the lenses correctly, and at any of the production stages. The use of a collaborative robot equipped with suitable vision sensors able to locate and identify the lenses, will be the most suitable solution. Structured-light 3D cameras will be used to solve the vision issues. |

|

|

| "Interactive Programming of flexible robots" |

"European industry is moving into the future, combining automation, artificial intelligence, Internet of Things (IoT), fundamentally looking to change the way it operates, evolving to “produce more and diverse with less”. SMARTHANDLE project will deploy several use cases which will research technologies to address these needs and support European industry." Read the full article |

|

|

"Advanced Machine Learning Approach in SMARTHANDLE" |

"Today’s robots are not smart enough for the next level of Industry 4.0. In order to support flexible automation, robots must be able to reliably detect and locate objects and human collaborators and varying illumination, work pieces type and locations, as the engineering of individual solutions is often costly and typically does not scale." Read the full article |

| |

|

"SMARTHANDLE - Advancing Human-Centric Robotics for Future Work Environments" |

| "Towards Digital Transformation: SMARTHANDLE EU project Industrial pilots" |

"As industrial environments extend integration activities of collaborative robotics, it becomes essential for humans to maintain a central role in the production process. Therefore, familiarizing the workforce with Industry 4.0 & 5.0 technologies is a foregone stepping-stone, bridging the gap between innovation and implementation." Read the full article |

|

|

"Addressing the complexities of human-robot collaboration requires a shift away from solely technology-focused approaches. Instead, a more comprehensive understanding of human-robot collaboration is essential. To proactively address these challenges, it becomes crucial to consider employees' perspectives and needs during the design and implementation of collaborative robotic systems." Read the full article |

| |

|

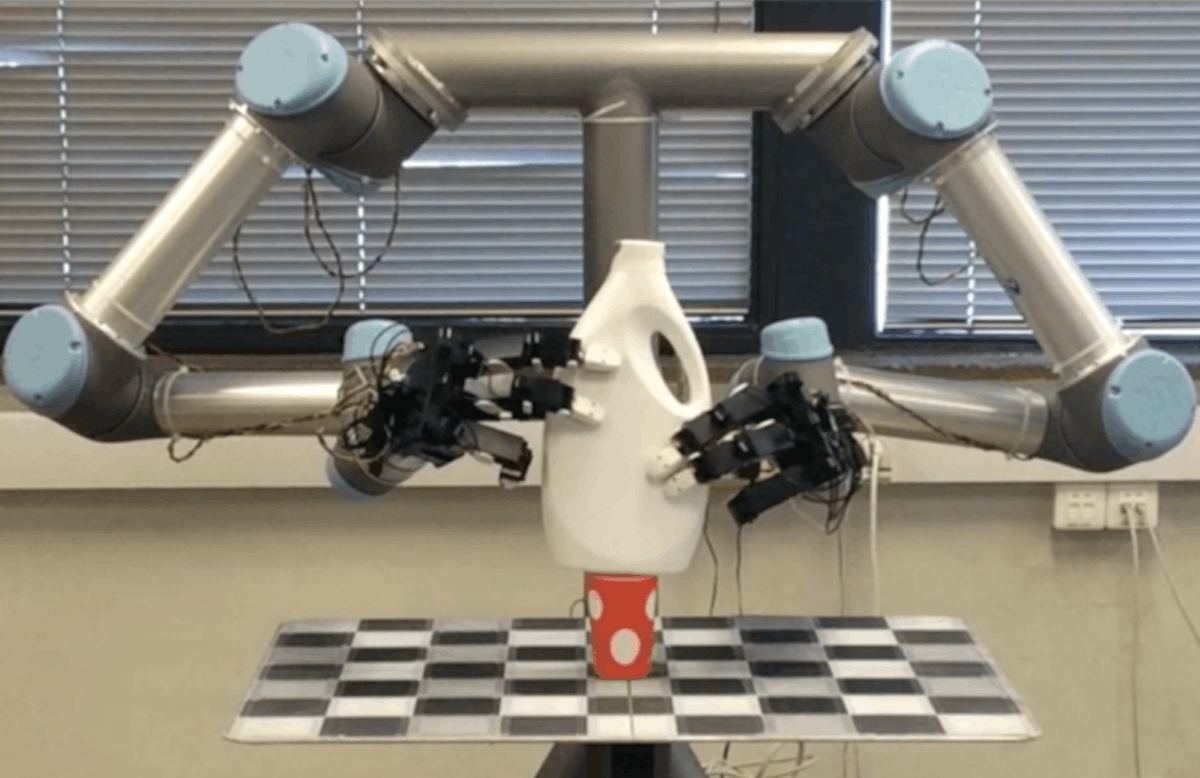

| "Grasping the Future: Revolutionizing Industrial Manipulation with SMARTHANDLE's AI-Powered Strategies" |

"The pursuit of "producing more and diverse with less" is accompanied by a series of challenges like the proliferation of product variants places a challenge on the development of reconfigurable and flexible handling tools and strategies, capable of seamlessly accommodating a wide array of product types." Read the full article |

|

|

One core ambition of European Union is to enhance the impact and effectiveness of its funding programs by promoting collaboration and mutual learning between projects and stakeholders of similar calls, leveraging each one's strengths and resources to achieve common goals. SMARTHANDLE embraces this ambition and emphasizes the importance of establishing synergies and clusters with partners of various backgrounds (academia and industry) to facilitate technology transfer, training and skill development. SMARTHANDLE has agreed upon common activities with the three projects of same European call: MASTERLY - (Nimble Artificial Intelligence driven robotic solutions for efficient and self-determined handling and assembly operations), HARTU - Handling with AI-enhanced Robotic Technologies for flexible manufacturing), AGILEHAND - Smart Grading, Handling and Packaging Solutions for Soft and Deformable Products in Agile and Reconfigurable Lines Read more |

|

|

The consortium of SMARTHANDLE consists of 14 partners from 6 countries (Greece, Spain, Germany, Netherlands, Luxemburg, and Belgium) who will join forces to develop, deploy, validate, and promote smart and versatile manufacturing solutions within the 3 years duration of the project. |

|

|

Follow us to stay tuned wtih SMARTHANDLE project! |

|

|

| |